Dostawcy Sruby oczkowe do podnoszenia

Ten produkt podlega następującym normom:

DIN 580 UNI 2947 BS 4278-1 DIN EN ISO 3266 BS 4278-2 BS 4278-3

Dane techniczne

Sruby oczkowe do podnoszenia

Ten produkt podlega następującym normom:

Standard DIN 580

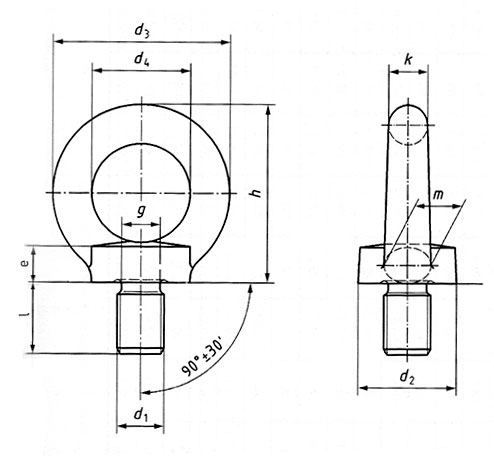

Sruby oczkowe do podnoszenia Niniejsza norma okres...Informacje zastrzeżone dla zarejestrowanych użytkowników: Zaloguj się | Zarejestruj się i rozpocznij 14 dniowy okres próbny!

| Dimensions in mm - source DIN 580 | ||||||||

| Publication date: 04/2018 Supersedes DIN 580 09/2010 | ||||||||

| d1 thread size | d2 nom | d3 nom | d4 nom | e nom | g nom | l nom | k nom | m nom |

| M 6 | 20 | 36 | 20 | 6 | 4.4 | 13 | 8 | 10 |

| M 8 | 20 | 36 | 20 | 6 | 6 | 13 | 8 | 10 |

| M 10 | ||||||||

| M 12 | ||||||||

| M 14 | ||||||||

| M 16 | ||||||||

| M 18 | ||||||||

| M 20 | ||||||||

| M 22 | ||||||||

| M 24 | ||||||||

| M 27 | ||||||||

| M 30 | ||||||||

| M 33 | ||||||||

| M 36 | ||||||||

| M 39 | ||||||||

| M 42 | ||||||||

| M 45 | ||||||||

| M 48 | ||||||||

| M 52 | ||||||||

| M 56 | ||||||||

| M 60 | ||||||||

| M 64 | ||||||||

| M 72x6 | ||||||||

| M 80x6 | ||||||||

| M 100x6 | ||||||||

| DIN 580 2018 - Lifting capacity | |||||||||||||

| d thread size | M6 | M8 | M10 | M12 | M 14 | M16 | M 18 | M20 | M 22 | M24 | M 27 | M30 | |

| Lifting capacity, WILL kg 0° |  | 75 | 140 | 230 | 340 | 490 | 700 | 850 | 1200 | 1400 | 1800 | 2100 | 3200 |

| Lifting capacity, WILL kg 45° |  | 55 | 100 | 170 | 240 | 350 | 500 | 600 | 860 | 1000 | 1290 | 1500 | 2300 |

| Lifting capacity, WILL kg 60° | |||||||||||||

| Lifting capacity, WILL kg 90° | |||||||||||||

| DIN 580 2018 - Lifting capacity | ||||||||||||||

| d thread size | M 33 | M 36 | M 39 | M42 | M 45 | M48 | M 52 | M56 | M 60 | M64 | M72X6 | M80X6 | M100X6 | |

| Lifting capacity, WILL kg 0° |  | 3200 | 4600 | 4600 | 6300 | 6300 | 8600 | 8600 | 11500 | 11500 | 16000 | 20000 | 28000 | 40000 |

| Lifting capacity, WILL kg 45° |  | 2300 | 3300 | 3300 | 4500 | 4500 | 6100 | 6100 | 8200 | 8200 | 11000 | 14000 | 20000 | 29000 |

| Lifting capacity, WILL kg 60° | ||||||||||||||

| Lifting capacity, WILL kg 90° | ||||||||||||||

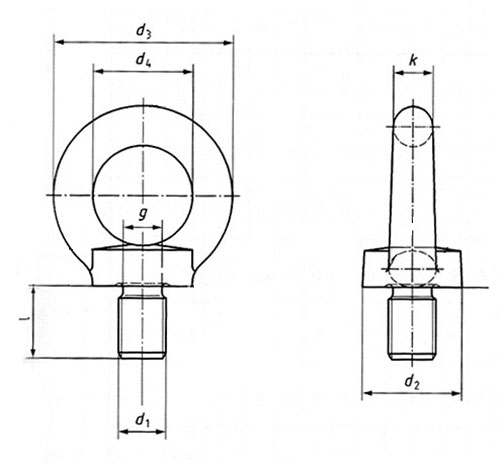

| Dimensions in mm - source DIN 580 | ||||||||||

| Publication date: 09/2010 Supersedes DIN 580 8/2003 | ||||||||||

| d1 thread size | WW thread | UNC thread | d2 nom | d3 nom | d4 nom | e nom | l nom | k nom | m nom | ~weigth, in kg x piece |

| M 8 | 1/4' | 1/4'-20 | 20 | 36 | 20 | 6 | 13 | 8 | 10 | 0.06 |

| M 8 | ||||||||||

| M 10 | ||||||||||

| M 12 | ||||||||||

| M 16 | ||||||||||

| M 20 | ||||||||||

| M 24 | ||||||||||

| M 24 | ||||||||||

| M 30 | ||||||||||

| M 36 | ||||||||||

| M 42 | ||||||||||

| M 48 | ||||||||||

| M 56 | ||||||||||

| M 64 | ||||||||||

| M 72x6 | ||||||||||

| M 80x6 | ||||||||||

| M 100x6 | ||||||||||

| Din 580 2010 - Lifting capacity | |||||||||

| d thread size | M8 | M10 | M12 | M16 | M20 | M24 | M30 | M36 | |

| Lifting capacity, axial per eye bolt kg |  | 140 | 230 | 340 | 700 | 1200 | 1800 | 3200 | 4600 |

| Lifting capacity per eye bolt ≤ 45° |  | 100 | 170 | 240 | 500 | 860 | 1290 | 2300 | 3300 |

| Lifting capacity per eye bolt, with bolt fitted at sides of load, ≤ 45° | |||||||||

| Din 580 2010 - Lifting capacity | ||||||||

| d thread size | M42 | M48 | M56 | M64 | M72X6 | M80X6 | M100X6 | |

| Lifting capacity, axial per eye bolt |  | 6300 | 8600 | 11500 | 16000 | 20000 | 28000 | 40000 |

| Lifting capacity per eye bolt ≤ 45° |  | 4500 | 6100 | 8200 | 11000 | 14000 | 20000 | 29000 |

| Lifting capacity per eye bolt, with bolt fitted at sides of load, ≤ 45° | ||||||||

Standard UNI 2947

Sruby oczkowe do podnoszenia, w pelni gwintowaneInformacje zastrzeżone dla zarejestrowanych użytkowników: Zaloguj się | Zarejestruj się i rozpocznij 14 dniowy okres próbny!

| Dimensions in mm - source UNI 2947 | |||||

| Publication date: 12-1948 | |||||

| d1 thread size | d2 nom | d3 nom | d4 nom | l nom | k nom |

| M 8 | 20 | 36 | 20 | 13 | 8 |

| M 10 | |||||

| M 12 | |||||

| M 16 | |||||

| M 20 | |||||

| M 24 | |||||

| M 30 | |||||

| M 36 | |||||

| M 42 | |||||

| M 48 | |||||

| M 56 | |||||

| M 64 | |||||

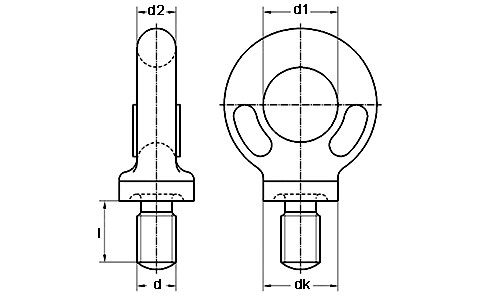

Standard BS 4278-1

Sruby oczkowe kolnierzowe do podnoszeniaInformacje zastrzeżone dla zarejestrowanych użytkowników: Zaloguj się | Zarejestruj się i rozpocznij 14 dniowy okres próbny!

| Dimensions in mm - source BS 4278-1 Withdrawn | ||||

| Publication date: 04/1984 | ||||

| d thread size | dk | d1 | d2 | l |

| M 12 | 22 | 15 | 9 | 18 |

| M 16 | ||||

| M 20 | ||||

| M 24 | ||||

| M 30 | ||||

| M 36 | ||||

| M 42 | ||||

| M 48 | ||||

| M 52 | ||||

| M 56 | ||||

| M 64 | ||||

| M 72 | ||||

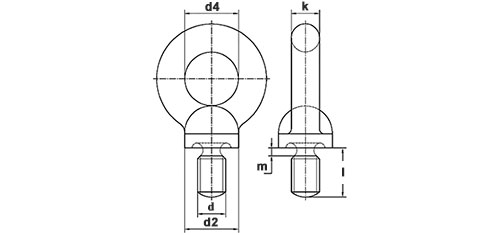

Standard DIN EN ISO 3266

Sruby oczkowe ze stali kutej klasy 4 do ogólnego p...Informacje zastrzeżone dla zarejestrowanych użytkowników: Zaloguj się | Zarejestruj się i rozpocznij 14 dniowy okres próbny!

| Dimensions in mm - source DIN EN ISO 3266 | ||||||

| Publication date: 05/2016 | ||||||

| d1 thread size | d2 nom | d4 nom | l nom | k nom | m nom | |

| M 8 | 17 | 9 | 12 | 6 | 2 | |

| M 10 | ||||||

| M 12 | ||||||

| M 16 | ||||||

| M 20 | ||||||

| M 24 | ||||||

| M 30 | ||||||

| M 36 | ||||||

| M 42 | ||||||

| M 48 | ||||||

| M 52 | ||||||

| M 56 | ||||||

| M 64 | ||||||

| M 72 | ||||||

| M 80 | ||||||

| M 90 | ||||||

| M 100 | ||||||

Standard BS 4278-2

Sruba oczkowa z ogniwemInformacje zastrzeżone dla zarejestrowanych użytkowników: Zaloguj się | Zarejestruj się i rozpocznij 14 dniowy okres próbny!

| Dimensions in mm - source BS4278-2 Withdrawn | |||||||||

| Publication date: 04/19847 | |||||||||

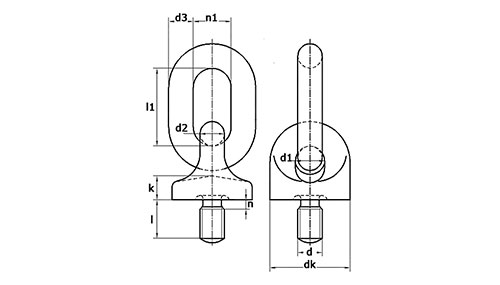

| 9d thread size | dk | d1 | d2 | d3 | n | l | k | n1 | l1 |

| M 20 | 39 | 15 | 12 | 13 | 4 | 27 | 12 | 24 | 53 |

| M 24 | |||||||||

| M 30 | |||||||||

| M 36 | |||||||||

| M 48 | |||||||||

Standard BS 4278-3

Sruba oczkowa dynamaInformacje zastrzeżone dla zarejestrowanych użytkowników: Zaloguj się | Zarejestruj się i rozpocznij 14 dniowy okres próbny!

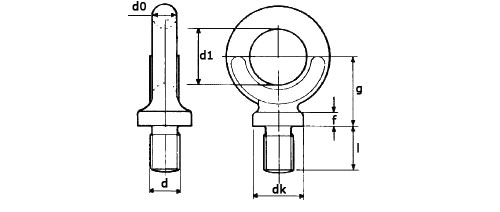

| Dimensions in mm - source BS4278-3 Withdrawn | ||||

| Publication date: 04/1984 | ||||

| d thread size | dk | d1 | d0 | l |

| M 12 | 17 | 22 | 9 | 18 |

| M 16 | ||||

| M 20 | ||||

| M 24 | ||||

| M 30 | ||||

| M 36 | ||||

| M 42 | ||||

| M 48 | ||||

| M 52 | ||||

Szczegóły

Sruby oczkowe do podnoszenia

Pełna lista dostawców Sruby oczkowe do podnoszenia

Manufacturer of wing nuts AF, wing screws AF, thumb screws, toothed plate connectors, beam clamps, channel, hexagon (domed) cap nuts

Spanish company manufacturing threaded rods and anchor bolts, with more than 40 years of experience in this field.

Production range: M-4 to M-80, in lengths from 20 mm to 6 meters in quality 4.8, 5.6, 6.8, 8.8, 10.9, 12.9 and stainless steel A2.

Manufacturer of cold forged parts: eye bolts, t-head bolts and clevis pins in steel and stainless steel.

Diameter 5–16mm and lengths up to 180mm

Manufacturer of hot forged fasteners, Eyebolts, shackles, holding down blts, U-bolts, hammerhead , T- Bolts and Special Bolts.

Hot forged parts from M10 to M100 and up to 6000 mm length.

Producer and distributor of many kinds of standard and nonstandard fasteners. Competitive products are: threaded rods, U bolts, nuts, washers, stampings parts, screws, bolts, chains, riggings, rivets, anchors. Material can be carbon steel, stainless steel, brass, nickel alloy and Titanium.

Manufacturer specialized in eye bolts, eye nuts and turnbuckles, both standard and special.

We operate in the production of lifting accessories, customized forged parts in steel and CNC-processing/machining. We also offer technical know how in the complex field of forging technology.

Certified following DIN 9001.

Manufacturer of hooks, eyebolts, U-bolts, studs, log bolts, foundation clamps, rods, pins, tie-rods, threaded bars and special chamfered-end bars

Manufacturer of parallel keys in metrich and inch sizes, clevis yokes, eye bolts and studs with hole.

Manufacturer of round steel chains, forged link chains, steel link chains and chain wheels in all dimensions, materials and standards.

Lifting accessories.

Distributor of chains, wire ropes, lifting accessories, eye nuts, shackles, turnbuckles and hooks

Distributor of lifting accessories, chains, hose clamps and nautical fixings in stainless steel

Manufacturer of lifting & rigging hardware, fasteners, CNC machined parts, stamping parts and custom industrial parts

Manufacturer and exporter of chains and lifting accessories: hooks, shackles, wire rope clips, turnbuckles, etc..

Exporter of lifting equipment, hooks, shackles, turnbuckles, chains and wire ropes.

Manufacturer specailized in lifting accessories: eye bolts, wire rope clips, shackles, turnbuckles, hooks, chains and wire rops.

Manufacturer of shackles, turnbuckles, clips, hooks, rings, thimbles, chains, stainless steel and marine hardware

We are a company specialized in the production of pipe clamps in small and big sizes and we can offer additional manufacturing, coatings, pre-assembly and Packing.

We manufacure

- Hose clamps

- Round steel bars, flat steel bars

-Pipe slides with accessories

- Tube supports following the customers requirements, drawings, samples in all standard norms.

Take time and feel free to ask for our offer and possibilities.

Manufacturer of nautical fixing products and lifting accessories in stainless steel