制造商和供应商 弧形弹簧锁紧垫圈

供应商完整名单

Leading manufacturer of stainless steel washers and compensation rings for ball bearings. Standard and special parts.

Biggest factory in China producing stainless steel washers.

Fat washers, spring washers, tooth lock washers and stamping parts.

Materials: 316L ,316S33,1.4462.

Manufacturer of blind rivets, solid rivets, fully tubular rivets, semi tubular rivets, bifurcated rivets

Manufacturer of standard and special washers in different materials, with internal diameter from 2.5 up to 80mm.

Manufacturer of washers and high quality safety shims. All materials: aluminium, bronze, iron and steel, stainless steel (A2, A4), copper, brass etc.

Producer of spring lock, toothed and special washers.

Quality Certificates: ISO 9001; ISO 14001; ISO/TS 16949

Manufacturer specialized in spring washers in different materials, also with double rings

Manufacturer of washers, disc springs, wave spring washers, serrated safety washers, Belleville washers, serrated washers & lockrite washers.

Fastener manufacturing company with more than 15 years experience.

Production range: all kinds of flat washers, spring washers, toothed washers, square washers, custom special washers.

Materials: stainless steel, carbon steel, brass.

Manufacturer of stainless steel flat washers, spring washers, square washers, tab washers, toothed lock washers and stamping parts

Manufacturer of Plain Washers, Flat Washers, Spring Washers & Special Sheet Metal & Wire Components, Din 127, Din 125, Din 9021.

Manufacturer specialized in washers. Production of 200,000 washers/day.

Flat, spring, toothed, square and wave washers, etc...

Manufacturer specialized in all kinds of Plain Washers, Spring and wire washers, Circlips, Copper washers, Aluminum washers, Star washers, Conical star washers, Serrated washers, Conical washers, Spherical washers.

Manufacturer of flat washers, spring washers, toothed washers, contact washers, belleville washers, spring washers, retaining rings, stamping parts.

Manufacturer of washers, cotter pins, linch pins, circlips, dowel pins, eye screws and wing nuts

Manufacturer of special washers and stampings in steel, stainless steel, alloy, copper, plastic

技术数据

弧形弹簧锁紧垫圈

本产品受以下标准管制:

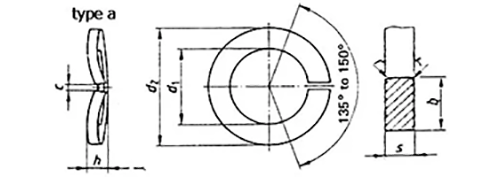

Standard DIN 128

弧形弹簧锁紧垫圈

本标准 DIN 128 涵盖的弹簧锁紧垫圈被视为设计用于螺栓/螺母组件的弹簧垫圈,该组件涉及 ISO 898 第 1 部分规定的强度等级低于 8.8 级的紧固件。它们旨在抵消因安装不当而导致螺栓/螺母组件松动的影响(参见 DIN 267 第 26 部分)。它们无法有效防止组件在变化的径向载荷下松动,并且设计用于主要承受推力的短螺栓。

|

|||||||||

|

Dimensions in mm - source DIN 128 - Withdrawn |

|||||||||

| Publication date: 10/1994 - Supersedes DIN 128: 10/1978 | |||||||||

|

d Nominal size |

Thread size | d min | d1 max | b nom | s nom | h min | r | ≈ mass in Kg x 1000 pcs (ρ=7,85 kg/dm3) | |

|

2

|

M 2

|

2.1

|

4.4

|

0.9 |

0.5

|

0.7

|

0.1 | 0.035 | |

|

2.5

|

M 2.5

|

2.6

|

5.1

|

1 |

0.6

|

0.9

|

0.1 | 0.055 | |

|

3

|

M 3

|

3.1

|

6.2

|

1.3 |

0.7

|

1.1

|

0.1 | 0.09 | |

|

3.5

|

M 3.5

|

3.6

|

6.7

|

1.3 |

0.7

|

1.1

|

0.1 | 0.1 | |

|

4

|

M 4

|

4.1

|

7.6

|

1.5 |

0.8

|

1.2

|

0.2 | 0.15 | |

|

5

|

M 5

|

5.1

|

9.2

|

1.8 |

1

|

1.5

|

0.2 | 0.3 | |

|

6

|

M 6

|

6.1

|

11.8

|

2.5 |

1.3

|

2

|

0.3 | 0.7 | |

|

7

|

M 7

|

7.1

|

12.8

|

2.5 |

1.3

|

2

|

0.3 | 0.75 | |

|

8

|

M 8

|

8.1

|

14.8

|

3 |

1.6

|

2.45

|

0.5 | 1.3 | |

|

10

|

M 10

|

10.2

|

18.1

|

3.5 |

1.8

|

2.85

|

0.5 | 2.1 | |

|

12

|

M 12

|

12.2

|

21.1

|

4 |

2.1

|

3.35

|

1 | 3.2 | |

|

14

|

M 14

|

14.2

|

24.1

|

4.9 |

2.4

|

3.9

|

1 | 4.8 | |

|

16

|

M 16

|

16.2

|

27.4

|

5 |

2.8

|

4.5

|

1 | 7 | |

|

18

|

M 18

|

18.2

|

29.4

|

5 |

2.8

|

4.5

|

1 | 7.8 | |

|

20

|

M 20

|

20.2

|

33.6

|

6 |

3.2

|

5.1

|

1 | 12.2 | |

|

22

|

M 22

|

22.5

|

35.9

|

6 |

3.2

|

5.1

|

1 | 13.3 | |

|

24

|

M 24

|

24.5

|

40.0

|

7 |

4.0

|

6.5

|

1.6 | 21.5 | |

|

27

|

M 27

|

27.5

|

43.0

|

7 |

4.0

|

6.5

|

1.6 | 23.7 | |

|

30

|

M 30

|

30.5

|

48.2

|

8 |

6.0

|

9.5

|

1.6 | 42.5 | |

|

36

|

M 36

|

36.5

|

58.2

|

10 |

6.0

|

10.3

|

1.6 | 68 | |

| 42 | M 42 | 42.5 | 68.2 | 12 | 7 | 12 | 2 | 111 | |

| 48 | M 48 | 49 | 75 | 12 | 7 | 12 | 2 | 123 | |

| 56 | M 56 | 57 | 87 | 14 | 8 | 14 | 2 | 193 | |

| 64 | M 64 | 65 | 95 | 14 | 8 | 14 | 2 | 218 | |

| 72 | M 72 | 73 | 103 | 14 | 8 | 14 | 2 | 240 | |

| 80 | M 80 | 81 | 111 | 14 | 8 | 14 | 2 | 262 | |

| 90 | M 90 | 91 | 121 | 14 | 8 | 14 | 2 | 290 | |

| 100 | M 100 | 101 | 131 | 14 | 8 | 14 | 2 | 318 | |

|

|||||||||

|

Dimensions in mm - source DIN 128 - Withdrawn |

|||||||||

| Publication date: 10/1987 - Supersedes DIN 128: 04/1968 | |||||||||

| Nominal size | Thread size | d min | d1 max | b | s nom | h min | r | ≈ mass in Kg x 1000 pcs (ρ=7,85 kg/dm3) | |

|

2

|

M 2

|

2.1

|

4.4

|

0.9 |

0.5

|

0.7

|

0.1 | 0.035 | |

|

2.5

|

M 2.5

|

2.6

|

5.1

|

1 |

0.6

|

0.9

|

0.1 | 0.055 | |

|

3

|

M 3

|

3.1

|

6.2

|

1.3 |

0.7

|

1.1

|

0.1 | 0.09 | |

|

3.5

|

M 3.5

|

3.6

|

6.7

|

1.3 |

0.7

|

1.1

|

0.1 | 0.1 | |

|

4

|

M 4

|

4.1

|

7.6

|

1.5 |

0.8

|

1.2

|

0.2 | 0.15 | |

|

5

|

M 5

|

5.1

|

9.2

|

1.8 |

1

|

1.5

|

0.2 | 0.3 | |

|

6

|

M 6

|

6.1

|

11.8

|

2.5 |

1.3

|

2

|

0.3 | 0.7 | |

|

7

|

M 7

|

7.1

|

12.8

|

2.5 |

1.3

|

2

|

0.3 | 0.75 | |

|

8

|

M 8

|

8.1

|

14.8

|

3 |

1.6

|

2.45

|

0.5 | 1.3 | |

|

10

|

M 10

|

10.2

|

18.1

|

3.5 |

1.8

|

2.85

|

0.5 | 2.1 | |

|

12

|

M 12

|

12.2

|

21.1

|

4 |

2.1

|

3.35

|

1 | 3.2 | |

|

14

|

M 14

|

14.2

|

24.1

|

4.9 |

2.4

|

3.9

|

1 | 4.8 | |

|

16

|

M 16

|

16.2

|

27.4

|

5 |

2.8

|

4.5

|

1 | 7 | |

|

18

|

M 18

|

18.2

|

29.4

|

5 |

2.8

|

4.5

|

1 | 7.8 | |

|

20

|

M 20

|

20.2

|

33.6

|

6 |

3.2

|

5.1

|

1 | 12.2 | |

|

22

|

M 22

|

22.5

|

35.9

|

6 |

3.2

|

5.1

|

1 | 13.3 | |

|

24

|

M 24

|

24.5

|

40.0

|

7 |

4.0

|

6.5

|

1.6 | 21.5 | |

|

27

|

M 27

|

27.5

|

43.0

|

7 |

4.0

|

6.5

|

1.6 | 23.7 | |

|

30

|

M 30

|

30.5

|

48.2

|

8 |

6.0

|

9.5

|

1.6 | 42.5 | |

|

36

|

M 36

|

36.5

|

58.2

|

10 |

6.0

|

10.3

|

1.6 | 68 | |

| 42 | M 42 | 42.5 | 68.2 | 12 | 7 | 12 | 2 | 111 | |

| 48 | M 48 | 49 | 75 | 12 | 7 | 12 | 2 | 123 | |

| 56 | M 56 | 57 | 87 | 14 | 8 | 14 | 2 | 193 | |

| 64 | M 64 | 65 | 95 | 14 | 8 | 14 | 2 | 218 | |

| 72 | M 72 | 73 | 103 | 14 | 8 | 14 | 2 | 240 | |

| 80 | M 80 | 81 | 111 | 14 | 8 | 14 | 2 | 262 | |

| 90 | M 90 | 91 | 121 | 14 | 8 | 14 | 2 | 290 | |

| 100 | M 100 | 101 | 131 | 14 | 8 | 14 | 2 | 318 | |

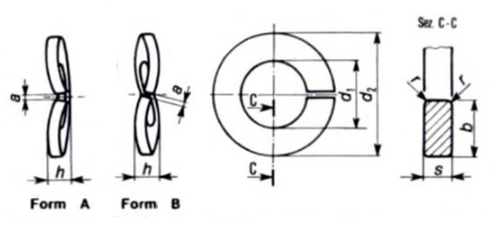

Standard UNI 8839

弯曲或皱褶的开口弹簧垫圈

|

Dimensions in mm - source UNI 8839 |

||||||||

| Publication date: 10/2013 - Supersedes UNI 8839: 04/1985 | ||||||||

|

d1Nominal size |

Thread size | d2 MAX | b nom | s nom | h min | h max | r | |

|

2.1

|

M 2

|

4.4

|

0.9 |

0.5

|

0.7

|

0.9 | 0.1 | |

| 2.4 | M 2.2 | 4.9 | 1 | 0.6 | 0.9 | 1.1 | 0.1 | |

|

2.6

|

M 2.5

|

5.1

|

1 |

0.6

|

0.9

|

1.1 | 0.1 | |

|

3.1

|

M 3

|

6.2

|

1.3 |

0.7

|

1.1

|

1.3 | 0.1 | |

|

3.6

|

M 3.5

|

6.7

|

1.3 |

0.7

|

1.1

|

1.3 | 0.1 | |

|

4.1

|

M 4

|

7.6

|

1.5 |

0.8

|

1.2

|

1.4 | 0.2 | |

|

5.1

|

M 5

|

9.2

|

1.8 |

1

|

1.5

|

1.7 | 0.2 | |

|

6.1

|

M 6

|

11.8

|

2.5 |

1.3

|

2

|

2.2 | 0.3 | |

|

7.1

|

M 7

|

12.8

|

2.5 |

1.3

|

2

|

2.2 | 0.3 | |

|

8.2

|

M 8

|

14.9

|

3 |

1.6

|

2.45

|

2.75 | 0.5 | |

|

10.2

|

M 10

|

18.1

|

3.5 |

1.8

|

2.85

|

3.15 | 0.5 | |

|

12.2

|

M 12

|

21.1

|

4 |

2.1

|

3.35

|

3.65 | 1 | |

|

14.2

|

M 14

|

24.1

|

4.5 |

2.4

|

3.9

|

4.3 | 1 | |

|

16.2

|

M 16

|

27.4

|

5 |

2.8

|

4.5

|

5.1 | 1 | |

|

18.2

|

M 18

|

29.4

|

5 |

2.8

|

4.5

|

5.1 | 1 | |

|

20.2

|

M 20

|

33.6

|

6 |

3.2

|

5.1

|

5.9 | 1 | |

|

22.5

|

M 22

|

35.9

|

6 |

3.2

|

5.1

|

5.9 | 1 | |

|

24.5

|

M 24

|

40.0

|

7 |

4.0

|

6.5

|

7.5 | 1.6 | |

|

27.5

|

M 27

|

43.0

|

7 |

4.0

|

6.5

|

7.5 | 1.6 | |

|

30.5

|

M 30

|

48.2

|

8 |

6.0

|

9.5

|

10.5 | 1.6 | |

|

36.5

|

M 36

|

58.2

|

10 |

6.0

|

10.3

|

11.3 | 1.6 | |

详细资料

弧形弹簧锁紧垫圈

|

尺寸(毫米)- 来源 DIN 128 - 已撤回 |

|||||||||

| 出版日期:1987年10月- 取代 DIN 128: 04/1968 | |||||||||

| 公称尺寸 | 螺纹尺寸 | d min | d1最大 | b | s nom | h min | r | ≈质量(千克 x 1000 件)(ρ=7.85 千克/立方分米) | |

|

2

|

M 2

|

2.1

|

4.4

|

0.9 |

0.5

|

0.7

|

0.1 | 0.035 | |

|

2.5

|

M 2.5

|

2.6

|

5.1

|

1 |

0.6

|

0.9

|

0.1 | 0.055 | |

|

3

|

M 3

|

3.1

|

6.2

|

1.3 |

0.7

|

1.1

|

0.1 | 0.09 | |

|

3.5

|

M 3.5

|

3.6

|

6.7

|

1.3 |

0.7

|

1.1

|

0.1 | 0.1 | |

|

4

|

M 4

|

4.1

|

7.6

|

1.5 |

0.8

|

1.2

|

0.2 | 0.15 | |

|

5

|

M 5

|

5.1

|

9.2

|

1.8 |

1

|

1.5

|

0.2 | 0.3 | |

|

6

|

M 6

|

6.1

|

11.8

|

2.5 |

1.3

|

2

|

0.3 | 0.7 | |

|

7

|

M 7

|

7.1

|

12.8

|

2.5 |

1.3

|

2

|

0.3 | 0.75 | |

|

8

|

M 8

|

8.1

|

14.8

|

3 |

1.6

|

2.45

|

0.5 | 1.3 | |

|

10

|

M 10

|

10.2

|

18.1

|

3.5 |

1.8

|

2.85

|

0.5 | 2.1 | |

|

12

|

M 12

|

12.2

|

21.1

|

4 |

2.1

|

3.35

|

1 | 3.2 | |

|

14

|

M 14

|

14.2

|

24.1

|

4.9 |

2.4

|

3.9

|

1 | 4.8 | |

|

16

|

M 16

|

16.2

|

27.4

|

5 |

2.8

|

4.5

|

1 | 7 | |

|

18

|

M 18

|

18.2

|

29.4

|

5 |

2.8

|

4.5

|

1 | 7.8 | |

|

20

|

M 20

|

20.2

|

33.6

|

6 |

3.2

|

5.1

|

1 | 12.2 | |

|

22

|

M 22

|

22.5

|

35.9

|

6 |

3.2

|

5.1

|

1 | 13.3 | |

|

24

|

M 24

|

24.5

|

40.0

|

7 |

4.0

|

6.5

|

1.6 | 21.5 | |

|

27

|

M 27

|

27.5

|

43.0

|

7 |

4.0

|

6.5

|

1.6 | 23.7 | |

|

30

|

M 30

|

30.5

|

48.2

|

8 |

6.0

|

9.5

|

1.6 | 42.5 | |

|

36

|

M 36

|

36.5

|

58.2

|

10 |

6.0

|

10.3

|

1.6 | 68 | |

| 42 | M 42 | 42.5 | 68.2 | 12 | 7 | 12 | 2 | 111 | |

| 48 | M 48 | 49 | 75 | 12 | 7 | 12 | 2 | 123 | |

| 56 | M 56 | 57 | 87 | 14 | 8 | 14 | 2 | 193 | |

| 64 | M 64 | 65 | 95 | 14 | 8 | 14 | 2 | 218 | |

| 72 | M 72 | 73 | 103 | 14 | 8 | 14 | 2 | 240 | |

| 80 | M 80 | 81 | 111 | 14 | 8 | 14 | 2 | 262 | |

| 90 | M 90 | 91 | 121 | 14 | 8 | 14 | 2 | 290 | |

| 100 | M 100 | 101 | 131 | 14 | 8 | 14 | 2 | 318 | |