Producenci i dostawcy Sruby oczkowe

Pełna lista dostawców

Manufacturer of U-bolts, bent wire parts, stampings, special screws and turned fasteners as per customer''s request

Manufacturer of cold forged parts: eye bolts, t-head bolts and clevis pins in steel and stainless steel.

Diameter 5–16mm and lengths up to 180mm

Manufacturer of hot forged fasteners, Eyebolts, shackles, holding down blts, U-bolts, hammerhead , T- Bolts and Special Bolts.

Hot forged parts from M10 to M100 and up to 6000 mm length.

Manufacturer specialized in eye bolts, eye nuts and turnbuckles, both standard and special.

Products in different product groups: Cleaning, Lubrication, Surface Treatment, Glues, Tapes, Electrical and Additives.

Manufacturer of hot forged eyebolts, T-head bolts and special cold and hot forged parts

Professional manufacturer in steel, alloy steel and stainless steel material.

Specialized in Hammer Head bolt, Eye bolt, DIN 938/939, any special and standard bolt.

Manufacturing factory and company was established in 1993. The company specializes in non-standard eyebolts in various sizes, lengths and materials (A2, A4, A2-50, A2-70, 4.6, 8.8, 10.9, 12.9, B7 and B8M). We offer cold forging and hot-forging treatments in order to meet different customers'' requirements. Your inquiries and purchase are welcome.

Dane techniczne

Sruby oczkowe

Ten produkt podlega następującym normom:

Standard DIN 444

- UNI 6058

|

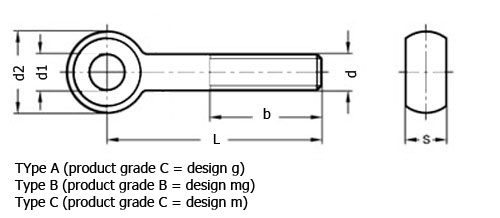

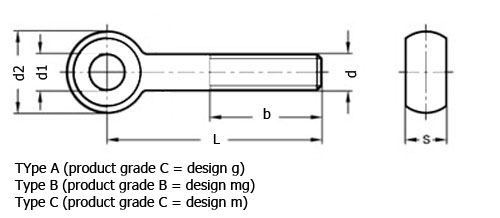

Dimensions in mm - source DIN 444 form A |

|||||||||

| Publication date: 04/1983 - Supersedes DIN 444: 10/1981 edition | |||||||||

| d thread size | P | b (l <=125) | b (l >125<=200) | b (l >200) | d1 | d2 min/max |

s min/max |

||

| M 5 | 0.8 | 16 | - | - | 5 | 10.9 | 12 | 7.52 | 8 |

| M 6 | 1 | 18 | - | - | 6 | 12.9 | 14 | 8.52 | 9 |

| M 8 | 1.25 | 22 | 28 | - | 8 | 16.9 | 18 | 10.30 | 11 |

| M 10 | 1.5 | 26 | 32 | - | 10 | 18.7 | 20 | 13.30 | 14 |

| M 12 | 1.75 | 30 | 36 | 49 | 12 | 23.7 | 25 | 16.30 | 17 |

| M 16 | 2 | 38 | 44 | 57 | 16 | 30.4 | 32 | 18.16 | 19 |

| M 20 | 2.5 | 46 | 52 | 65 | 18 | 38.4 | 40 | 23.16 | 24 |

| M 24 | 3 | 54 | 60 | 73 | 22 | 43.4 | 45 | 27.16 | 28 |

| M 27 | 3 | 60 | 66 | 79 | 24/25 | 48.4 | 50 | 29.16 | 30 |

| M 30 | 3.5 | 66 | 72 | 85 | 27/28 | 53.1 | 55 | 33 | 34 |

| M 33 | 3.5 | - | 78 | 91 | 30 | 58.1 | 60 | 37 | 38 |

| M 36 | 4 | - | 84 | 97 | 32/33 | 63.1 | 65 | 40 | 41 |

| M 39 | 4 | - | 90 | 103 | 35/36 | 68.1 | 70 | 45 | 46 |

| Designation example: Eyebolt DIN 444 A M10 x 60 - 4.6 | |||||||||

|

Dimensions in mm - source Din 444. form B (product grade B=design mg). form C (product grade A=design m) |

|||||||||

| Publication date: 04/1983 - Supersedes DIN 444: 10/1981 edition | |||||||||

| d thread size | P | b (l <=125) | b (l >125<=200) | b (l >200) | d1 | d2 min/max |

s min/max |

||

| M 5 | 0.8 | 16 | - | - | 5 | 11.57 | 12 | 5.88 | 6 |

| M 6 | 1 | 18 | - | - | 6 | 13.57 | 14 | 6.85 | 7 |

| M 8 | 1.25 | 22 | 28 | - | 8 | 17.57 | 18 | 8.85 | 9 |

| M 10 | 1.5 | 26 | 32 | - | 10 | 19.48 | 20 | 11.82 | 12 |

| M 12 | 1.75 | 30 | 36 | 49 | 12 | 24.48 | 25 | 13.82 | 14 |

| M 16 | 2 | 38 | 44 | 57 | 16 | 31.38 | 32 | 16.82 | 17 |

| M 20 | 2.5 | 46 | 52 | 65 | 18 | 39.38 | 40 | 21.79 | 22 |

| M 24 | 3 | 54 | 60 | 73 | 22 | 44.38 | 45 | 24.79 | 25 |

| M 27 | 3 | 60 | 66 | 79 | 24/25 | 49.38 | 50 | 26.79 | 27 |

| M 30 | 3.5 | 66 | 72 | 85 | 27/28 | 54.26 | 55 | 29.79 | 30 |

| M 33 | 3.5 | - | 78 | 91 | 30 | 59.26 | 60 | 33.75 | 34 |

| M 36 | 4 | - | 84 | 97 | 32/33 | 64.26 | 65 | 37.75 | 38 |

| M 39 | 4 | - | 90 | 103 | 35/36 | 69.26 | 70 | 40.75 | 41 |

| Designation example: Eyebolt DIN 444 A M10 x 60 - 4.6 | |||||||||

|

Din 444 - Approximate mass, in kg x1000 pcs, (ρ=7,85 kg/dm3) - commercial lengths |

|||||||||||||

| d thread size |

M5

|

M6

|

M8

|

M10

|

M12

|

M16

|

M20

|

M24 | M27 | M30 | M33 | M36 | M39 |

| nominal length l | |||||||||||||

| 30 | 7.93 | ||||||||||||

| 35 | 8.70 | 12.6 | |||||||||||

| 40 | 9.47 | 13.7 | 25 | ||||||||||

| 45 | 10.3 | 14.8 | 26.9 | 36 | |||||||||

| 50 | 11 | 15.9 | 28.9 | 39.1 | |||||||||

| 55 | 11.8 | 17 | 30.9 | 42.2 | 67 | ||||||||

| 60 | 12.6 | 18.1 | 32.8 | 45.3 | 71.4 | ||||||||

| 65 | 13.3 | 19.2 | 34.8 | 48.4 | 75.8 | ||||||||

| 70 | 14.1 | 20.3 | 36.8 | 51.5 | 80.3 | 149 | |||||||

| 75 | 14.9 | 21.5 | 38.8 | 54.6 | 84.8 | 157 | |||||||

| 80 | 15.7 | 22.6 | 40.7 | 57.6 | 89.2 | 164 | |||||||

| 90 | 23.7 | 44.7 | 63.8 | 98.1 | 180 | ||||||||

| 100 | 48.6 | 70 | 106 | 196 | 334 | 454 | |||||||

| 110 | 52.6 | 76.1 | 115 | 212 | 359 | 489 | |||||||

| 120 | 56.5 | 82.3 | 124 | 228 | 383 | 524 | 618 | ||||||

| 130 | 60.35 | 88.4 | 133 | 244 | 408 | 560 | 663 | ||||||

| 140 | 64.4 | 94.5 | 142 | 259 | 433 | 596 | 708 | ||||||

| 150 | 101 | 151 | 275 | 457 | 631 | 753 | 997 | 1240 | |||||

| 160 | 160 | 291 | 482 | 667 | 798 | 1050 | 1310 | 1570 | 1880 | ||||

| 180 | 178 | 322 | 531 | 738 | 888 | 1160 | 1440 | 1730 | 2070 | ||||

| 200 | 195 | 354 | 581 | 809 | 978 | 1270 | 1570 | 1890 | 2250 | ||||

| 220 | 211 | 383 | 624 | 868 | 1060 | 1370 | 1690 | 2050 | 2420 | ||||

| 240 | 229 | 414 | 674 | 939 | 1140 | 1480 | 1820 | 2200 | 2610 | ||||

| 260 | 247 | 446 | 723 | 1010 | 1230 | 1590 | 1960 | 2350 | 2790 | ||||

| 280 | 1320 | 1700 | 2100 | 2500 | 2970 | ||||||||

| 300 | 1400 | 1810 | 2240 | 2650 | 3100 | ||||||||

Standard UNI 6058

Norma DIN 444 okresla sruby oczkowe z gwintem metrycznym od M5 do M39 klasy produktu A, B i C.

|

Dimensions in mm - source Uni 6058 1967 |

||||

| d thread size | d1 min | d1 max | d2max | s max |

| M 4 | 3.06 | 3.14 | 8 | 5 |

| M 5 | 4.075 | 4.14 | 10 | 6 |

| M 6 | 5.075 | 5.14 | 12 | 7 |

| M 8 | 6.075 | 6.14 | 16 | 9 |

| M 10 | 8.09 | 8.15 | 20 | 12 |

| M 12 | 10.09 | 10.15 | 24 | 14 |

| M 14 | 12.11 | 12.15 | 28 | 16 |

| M 16 | 14.11 | 14.15 | 32 | 18 |

| M 18 | 16..1 | 16.15 | 36 | 20 |

| M 20 | 18.11 | 18.15 | 40 | 22 |

| M 22 | 18.11 | 18.15 | 44 | 24 |

| M 24 | 20.13 | 20.16 | 48 | 26 |

| M 27 | 22.13 | 22.16 | 54 | 30 |

| M 30 | 25.13 | 25.16 | 60 | 33 |

Szczegóły

Sruby oczkowe

|

Wymiary w mm - zródlo: DIN 444, forma A |

|||||||||

| Data publikacji: 04/1983 - Zastepuje DIN 444: wydanie 10/1981 | |||||||||

| gwint d rozmiar | P | b (l >=125) | b (l >125<=200) | b (l >200) | d1 | d2 min/maks |

s min/maks |

||

| M 5 | 0,8 | 16 | - | - | 5 | 10,9 | 12 | 7,52 | 8 |

| M 6 | 1 | 18 | - | - | 6 | 12,9 | 14 | 8,52 | 9 |

| M 8 | 1,25 | 22 | 28 | - | 8 | 16,9 | 18 | 10,30 | 11 |

| M 10 | 1,5 | 26 | 32 | - | 10 | 18,7 | 20 | 13,30 | 14 |

| M 12 | 1,75 | 30 | 36 | 49 | 12 | 23,7 | 25 | 16.30 | 17 |

| M 16 | 2 | 38 | 44 | 57 | 16 | 30,4 | 32 | 18,16 | 19 |

| M 20 | 2,5 | 46 | 52 | 65 | 18 | 38,4 | 40 | 23,16 | 24 |

| M 24 | 3 | 54 | 60 | 73 | 22 | 43,4 | 45 | 27,16 | 28 |

| M 27 | 3 | 60 | 66 | 79 | 24/25 | 48,4 | 50 | 29,16 | 30 |

| M 30 | 3,5 | 66 | 72 | 85 | 27/28 | 53,1 | 55 | 33 | 34 |

| M 33 | 3,5 | - | 78 | 91 | 30 | 58,1 | 60 | 37 | 38 |

| M 36 | 4 | - | 84 | 97 | 32/33 | 63.1 | 65 | 40 | 41 |

| M 39 | 4 | - | 90 | 103 | 35/36 | 68,1 | 70 | 45 | 46 |

| Przyklad oznaczenia: Sruba oczkowa DIN 444 A M10 x 60 - 4,6 | |||||||||

|

Wymiary w mm - zródlo DIN 444. forma B (gatunek produktu B = projekt mg). forma C (klasa produktu A = projekt m) |

|||||||||

| Data publikacji: 04/1983 - Zastepuje norme DIN 444: wydanie 10/1981 | |||||||||

| d rozmiar gwintu | P | b (l <=125) | b (l >125<=200) | b (l >200) | d1 | d2 min/maks |

s min/max |

||

| M 5 | 0,8 | 16 | - | - | 5 | 11,57 | 12 | 5,88 | 6 |

| M 6 | 1 | 18 | - | - | 6 | 13,57 | 14 | 6,85 | 7 |

| M 8 | 1,25 | 22 | 28 | - | 8 | 17,57 | 18 | 8,85 | 9 |

| M 10 | 1,5 | 26 | 32 | - | 10 | 19,48 | 20 | 11,82 | 12 |

| M 12 | 1,75 | 30 | 36 | 49 | 12 | 24,48 | 25 | 13,82 | 14 |

| M 16 | 2 | 38 | 44 | 57 | 16 | 31,38 | 32 | 16,82 | 17 |

| M 20 | 2,5 | 46 | 52 | 65 | 18 | 39,38 | 40 | 21,79 | 22 |

| M 24 | 3 | 54 | 60 | 73 | 22 | 44,38 | 45 | 24,79 | 25 |

| M 27 | 3 | 60 | 66 | 79 | 24/25 | 49,38 | 50 | 26,79 | 27 |

| M 30 | 3,5 | 66 | 72 | 85 | 27/28 | 54,26 | 55 | 29,79 | 30 |

| M 33 | 3,5 | - | 78 | 91 | 30 | 59,26 | 60 | 33,75 | 34 |

| M 36 | 4 | - | 84 | 97 | 32/33 | 64,26 | 65 | 37,75 | 38 |

| M 39 | 4 | - | 90 | 103 | 35/36 | 69,26 | 70 | 40,75 | 41 |

| Przyklad oznaczenia: Sruba oczkowa DIN 444 A M10 x 60 - 4,6 | |||||||||

|

Wymiary w mm - zródlo Uni 6058 1967 |

||||

| d rozmiar gwintu | d1 min | d1 max | d2max | s max |

| M 4 | 3,06 | 3,14 | 8 | 5 |

| M 5 | 4,075 | 4,14 | 10 | 6 |

| M 6 | 5,075 | 5,14 | 12 | 7 |

| M 8 | 6,075 | 6,14 | 16 | 9 |

| M 10 | 8,09 | 8,15 | 20 | 12 |

| M 12 | 10,09 | 10,15 | 24 | 14 |

| M 14 | 12.11 | 12.15 | 28 | 16 |

| M 16 | 14,11 | 14,15 | 32 | 18 |

| M 18 | 16..1 | 16.15 | 36 | 20 |

| M 20 | 18,11 | 18,15 | 40 | 22 |

| M 22 | 18,11 | 18,15 | 44 | 24 |

| M 24 | 20.13 | 20.16 | 48 | 26 |

| M 27 | 22,13 | 22,16 | 54 | 30 |

| M 30 | 25,13 | 25,16 | 60 | 33 |

|

Din 444 - Przyblizona masa, w kg x 1000 szt., (ρ=7,85 kg/dm3) - dlugosci handlowe |

|||||||||||||||

| d rozmiar gwintu |

M5

|

M6

|

M8

|

M10

|

M12

|

M16

|

M20

|

M24 | M27 | M30 | M33 | M36 | M39 | ||

| dlugosc nominalna l | |||||||||||||||

| 30 | 7,93 | ||||||||||||||

| 35 | 8,70 | 12,6 | align='center'> | ||||||||||||

| 40 | 9,47 | 13,7 | 25 | ||||||||||||

| 45 | 10,3 | 14,8 | 26,9 | 36 | align='center'> | ||||||||||

| 50 | 11 | 15,9 | 28,9 | 39,1 | |||||||||||

| 55 | 11,8 | 17 | 30,9 | 42,2 | 67 | ||||||||||

| 60 | 12,6 | 18,1 | 32,8 | 45,3 | 71,4 | ||||||||||

| 65 | 13,3 | 19,2 | 34,8 | 48,4 | 75,8 | ||||||||||

| 70 | 14,1 | 20,3 | 36,8 | 51,5 | 80,3 | 149 | |||||||||

| 75 | 14,9 | 21,5 | 38,8 | 54,6 | 84,8 | 157 | align='center'> | ||||||||

| 80 | 15,7 | 22,6 | 40,7 | 57,6 | 89,2 | 164 | |||||||||

| 90 | 23,7 | 44,7 | 63,8 | 98,1 | 180 | ||||||||||

| 100 | 48,6 | 70 | 106 | 196 | 334 | 454 | |||||||||

| 110 | 52,6 | 76,1 | 115 | 212 | 359 | 489 | align='center'> | ||||||||

| 120 | 56,5 | 82,3 | 124 | 228 | 383 | 524 | 618 | ||||||||

| 130 | 60,35 | 88,4 | 133 | 244 | 408 | 560 | 663 | ||||||||

| 140 | 64,4 | 94,5 | 142 | 259 | 433 | 596 | 708 | ||||||||

| 150 | 101 | 151 | 275 | 457 | 631 | 753 | 997 | 1240 | |||||||

| 160 | 160 | 291 | 482 | 667 | 798 | 1050 | 1310 | 1570 | 1880 | ||||||

| 180 | 178 | 322 | 531 | 738 | 888 | 1160 | 1440 | 1730 | 2070 | ||||||

| 200 | 195 | 354 | 581 | 809 | 978 | 1270 | 1570 | 1890 | 2250 | ||||||

| 220 | 211 | 383 | 624 | 868 | 1060 | 1370 | 1690 | 2050 | 2420 | ||||||

| 240 | 229 | 414 | 674 | 939 | 1140 | 1480 | 1820 | 2200 | 2610 | ||||||

| 260 | 247 | 446 | 723 | 1010 | 1230 | 1590 | 1960 | 2350 | 2790 | ||||||

| 280 | 1320 | 1700 | 2100 | 2500 | 2970 | ||||||||||

| 300 | 1400 | 1810 | 2240 | 2650 | 3100 | ||||||||||