Manufacturers & Suppliers of Studs and ceramic ferrules for arc stud welding

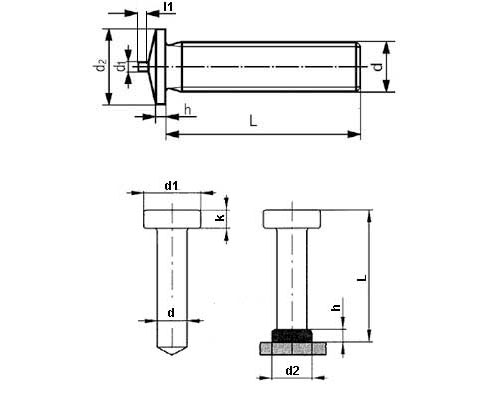

This product is regulated by the following standards:

DIN EN ISO 13918 (Equivalent standards: BS EN ISO 13918, NF EN ISO 13918, UNI EN ISO 13918)

Full List of Suppliers

FIXI, founded in 1984, it's an italian distributor of fastening system specialized in blind rivets, rivet nuts, self-clinching, welding studs, inserts for plastic, wire inserts, inserts for tubes, self-tapping inserts, inserts for stone and fasteners for the composite world.

Production of special items following the customer drawing: special screws, rivets, half bored rivets, pins, spacers and sleeves.

Materials: iron, stainless steel, copper, brass, aluminium with heat and galvanic treatments.

Leader in Italy for the production and distribution of fixing systems and tools for sheet metal working

.jpg)