Hersteller und Lieferanten von Nasenhohlkeile, Spannungsverbindungen mit Anzug

Dieses Produkt unterliegt den folgenden Normen:

Vollständige Lieferantenliste

Hersteller von Spannstiften, Zylindrischen und konischen Stiften, Kerbstiften, Winkelgelenken und Kugelzapfen

Hersteller von Nutmuttern, Stellringen, Passfedern, Präzisionsdrehteilen fÜr alle Industriezweige nach eigener Werknorm, nach DIN sowie nach Zeichnung oder Muster

Hersteller von Flachkeilen in metrischen- und Zollabmessungen, GabelkÖpfen, Ring- und Augenschrauben.

Hersteller von Sicherungsringe, Sprengringe, Scheiben, Scheibenfedern, Federstifte, SchlÜssel.

Hersteller von Zylinderstiften, Spannstiften, Kegelstifte, Stiften mit Schlitz und Keilen.

Hersteller von GabelkÖpfen, Gabelgelenken, Winkelgelenken, GelenkÖpfen, Sicherungselementen

Technische Daten

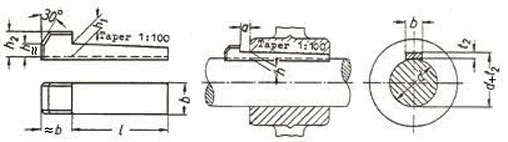

Nasenhohlkeile, Spannungsverbindungen mit Anzug

Dieses Produkt unterliegt den folgenden Normen:

Standard DIN 6889

Nasenhohlkeile, Spannungsverbindungen mit Anzug; Abmessungen und Anwendungen

|

Dimensions in mm - source DIN 6889 |

||||||||||||

| Publication date: 02/1956 | ||||||||||||

| key width b h9 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 25 | 28 | 32 | 36 |

| key heigth h nom | 3.5 | 4 | 4 | 4.5 | 5 | 5 | 6 | 7 | 7 | 7.5 | 8.5 | 9 |

| for shaft diameters d (over÷to) | 22÷30 | 30÷38 | 38÷44 | 44÷50 | 50÷58 | 58÷65 | 65÷75 | 75÷85 | 85÷95 | 95÷110 | 110÷130 | 130÷150 |

| groove width b D 10 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 25 | 28 | 32 | 36 |

| radius r1 | 15 | 19 | 22 | 25 | 29 | 33 | 38 | 43 | 48 | 55 | 65 | 75 |

| groove depth t2 | 3.2 | 3.7 | 3.7 | 4 | 4.5 | 4.5 | 5.5 | 6.5 | 6.4 | 6.9 | 7.9 | 8.4 |

|

DIN 6889 - ≈ weigth in kg x1000 pcs, (ρ=7,85 kg/dm3) - commercial items |

||||||||||||

| key width b h9 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 25 | 28 | 32 | 36 |

| key heigth h nom | 3.5 | 4 | 4 | 4.5 | 5 | 5 | 6 | 7 | 7 | 7.5 | 8.5 | 9 |

| nominal length l | ||||||||||||

| 20 | 8.56 | |||||||||||

| 22 | 9.03 | |||||||||||

| 25 | 9.73 | 14.9 | ||||||||||

| 28 | 10.4 | 15.9 | ||||||||||

| 32 | 11.4 | 17.2 | 22.5 | |||||||||

| 36 | 12.3 | 18.5 | 24.1 | |||||||||

| 40 | 13.3 | 19.8 | 25.6 | 36 | ||||||||

| 45 | 14.4 | 21.5 | 27.6 | 38.6 | 53.1 | |||||||

| 50 | 15.5 | 23.1 | 29.5 | 41.2 | 56.4 | 67.7 | ||||||

| 56 | 16.8 | 25 | 31.8 | 44.3 | 60.3 | 72.2 | 102 | |||||

| 63 | 18.3 | 27.1 | 34.6 | 47.8 | 64.8 | 77.3 | 109 | 139 | ||||

| 70 | 19.8 | 29.3 | 37.2 | 51.3 | 69.2 | 82.4 | 115 | 148 | 192 | |||

| 80 | 21.8 | 32.2 | 40.8 | 56.2 | 75.6 | 89.7 | 125 | 161 | 206 | 264 | ||

| 90 | 23.7 | 35.1 | 44.3 | 61.1 | 81.8 | 96.9 | 135 | 173 | 220 | 281 | 383 | |

| 100 | 38 | 47.7 | 65.6 | 87.8 | 104 | 144 | 185 | 234 | 298 | 405 | 526 | |

| 110 | 40.8 | 51.2 | 70.2 | 93.7 | 111 | 152 | 197 | 247 | 315 | 427 | 554 | |

| 125 | 56.1 | 76.9 | 102 | 121 | 166 | 215 | 267 | 339 | 459 | 593 | ||

| 140 | 60.4 | 83.3 | 110 | 130 | 179 | 232 | 287 | 363 | 491 | 632 | ||

| 160 | 91.1 | 121 | 142 | 196 | 254 | 313 | 395 | 532 | 683 | |||

| 180 | 131 | 154 | 213 | 275 | 338 | 426 | 573 | 733 | ||||

| 200 | 165 | 228 | 296 | 362 | 456 | 613 | 782 | |||||

| 220 | 243 | 316 | 386 | 485 | 653 | 829 | ||||||

| 250 | 346 | 419 | 525 | 707 | 897 | |||||||

| 280 | 451 | 564 | 761 | 964 | ||||||||

| 315 | 608 | 821 | 1040 | |||||||||

| 355 | 886 | 1120 | ||||||||||

| 400 | 1205 | |||||||||||

Daten

Nasenhohlkeile, Spannungsverbindungen mit Anzug

|

Dimensions in mm - source DIN 6889 |

||||||||||||

| Publication date: 02/1956 | ||||||||||||

| key width b h9 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 25 | 28 | 32 | 36 |

| key heigth h nom | 3.5 | 4 | 4 | 4.5 | 5 | 5 | 6 | 7 | 7 | 7.5 | 8.5 | 9 |

| for shaft diameters d (over÷to) | 22÷30 | 30÷38 | 38÷44 | 44÷50 | 50÷58 | 58÷65 | 65÷75 | 75÷85 | 85÷95 | 95÷110 | 110÷130 | 130÷150 |

| groove width b D 10 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 25 | 28 | 32 | 36 |

| radius r1 | 15 | 19 | 22 | 25 | 29 | 33 | 38 | 43 | 48 | 55 | 65 | 75 |

| groove depth t2 | 3.2 | 3.7 | 3.7 | 4 | 4.5 | 4.5 | 5.5 | 6.5 | 6.4 | 6.9 | 7.9 | 8.4 |

|

DIN 6889 - ≈ weigth in kg x1000 pcs, (ρ=7,85 kg/dm3) - commercial items |

||||||||||||

| key width b h9 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 25 | 28 | 32 | 36 |

| key heigth h nom | 3.5 | 4 | 4 | 4.5 | 5 | 5 | 6 | 7 | 7 | 7.5 | 8.5 | 9 |

| nominal length l | ||||||||||||

| 20 | 8.56 | |||||||||||

| 22 | 9.03 | |||||||||||

| 25 | 9.73 | 14.9 | ||||||||||

| 28 | 10.4 | 15.9 | ||||||||||

| 32 | 11.4 | 17.2 | 22.5 | |||||||||

| 36 | 12.3 | 18.5 | 24.1 | |||||||||

| 40 | 13.3 | 19.8 | 25.6 | 36 | ||||||||

| 45 | 14.4 | 21.5 | 27.6 | 38.6 | 53.1 | |||||||

| 50 | 15.5 | 23.1 | 29.5 | 41.2 | 56.4 | 67.7 | ||||||

| 56 | 16.8 | 25 | 31.8 | 44.3 | 60.3 | 72.2 | 102 | |||||

| 63 | 18.3 | 27.1 | 34.6 | 47.8 | 64.8 | 77.3 | 109 | 139 | ||||

| 70 | 19.8 | 29.3 | 37.2 | 51.3 | 69.2 | 82.4 | 115 | 148 | 192 | |||

| 80 | 21.8 | 32.2 | 40.8 | 56.2 | 75.6 | 89.7 | 125 | 161 | 206 | 264 | ||

| 90 | 23.7 | 35.1 | 44.3 | 61.1 | 81.8 | 96.9 | 135 | 173 | 220 | 281 | 383 | |

| 100 | 38 | 47.7 | 65.6 | 87.8 | 104 | 144 | 185 | 234 | 298 | 405 | 526 | |

| 110 | 40.8 | 51.2 | 70.2 | 93.7 | 111 | 152 | 197 | 247 | 315 | 427 | 554 | |

| 125 | 56.1 | 76.9 | 102 | 121 | 166 | 215 | 267 | 339 | 459 | 593 | ||

| 140 | 60.4 | 83.3 | 110 | 130 | 179 | 232 | 287 | 363 | 491 | 632 | ||

| 160 | 91.1 | 121 | 142 | 196 | 254 | 313 | 395 | 532 | 683 | |||

| 180 | 131 | 154 | 213 | 275 | 338 | 426 | 573 | 733 | ||||

| 200 | 165 | 228 | 296 | 362 | 456 | 613 | 782 | |||||

| 220 | 243 | 316 | 386 | 485 | 653 | 829 | ||||||

| 250 | 346 | 419 | 525 | 707 | 897 | |||||||

| 280 | 451 | 564 | 761 | 964 | ||||||||

| 315 | 608 | 821 | 1040 | |||||||||

| 355 | 886 | 1120 | ||||||||||

| 400 | 1205 | |||||||||||